- Industry: Resort Hotel and Casino Facility

- Application: Evaporative cooling water system (500 m3/day makeup)

- Problem: High freshwater usage and costs. On-site treated wastewater available to use as cooling tower makeup water, but with significantly increased risk for biofouling and associated problems.

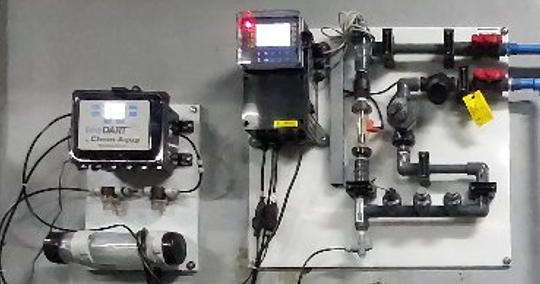

- Solution: Chem-Aqua’s Get Clean, Keep Clean program was implemented which involved filtration, improved chemical feed and monitoring with aquaDART® Automation Control and a bioDART® Biofouling Monitor, and patented bioeXile® biofilm removal technology.

- Result: 180,000 m3/yr reduced freshwater usage resulted in $330,000 USD/yr cost savings.

Problem

Due to the hot climate, a large volume of water was required to operate the cooling tower system at a resort hotel and casino in Asia. No additional water savings were available from increasing the cycles of concentration. An alternative was needed to reduce freshwater usage and overall operating costs.

Chem-Aqua Solution

The facility generates a large volume of wastewater daily which was processed in a biological treatment plant prior to discharge. Compared to freshwater, the treated wastewater presented several challenges for use as cooling tower makeup water:

- 14x TSS (Total Suspended Solids)

- 6x Turbidity

- 5x Bacteria count

- 2.5x Conductivity

To address the significantly increased risk of biofouling, Chem-Aqua applied a comprehensive, multi-step Get Clean, Keep Clean program for enhanced treatment, monitoring, and program management. Key elements include:

- aquaDART Automation Control System

- bioDART Biofouling Monitor

- bioeXile biofilm removal chemistry

- Multi-stage filtration

- Structured sampling, monitoring, and chemical program

- Expert chemical treatment program management

Results

The Get Clean, Keep Clean approach successfully allowed the use of the recycled water for multiple years:

- bioDART monitor showed consistent biofilm and biofouling control

- Chiller approach temperatures maintained at

1.5 – 2.0 °C - Sustainability increased by reusing 500 m3/day of wastewater

- Project saved nearly $330,000 USD annually

Contact Us Today

Transform your water treatment strategy with aquaDART™ and experience unparalleled control, efficiency, and cost savings. Reach out to our team at Chem-Aqua to discuss how aquaDART™ can elevate your water system performance.