Chem-Aqua's Approach to Water Treatment

At Chem-Aqua, we take a comprehensive approach to optimise the efficiency and longevity of heated water systems, including steam boilers and hot closed-loop systems. By combining advanced technology with expert support, we address the critical aspects of water treatment for reliable long-term performance.

Detailed Survey & Customised Solutions

We begin with an in-depth site survey to analyse the unique operation of your heated water systems. Based on this assessment, we create a customised water treatment programme designed to maximise efficiency, reduce risks such as scaling, deposition and corrosion for safe and reliable performance.

Chemical Dosing & Blowdown Management

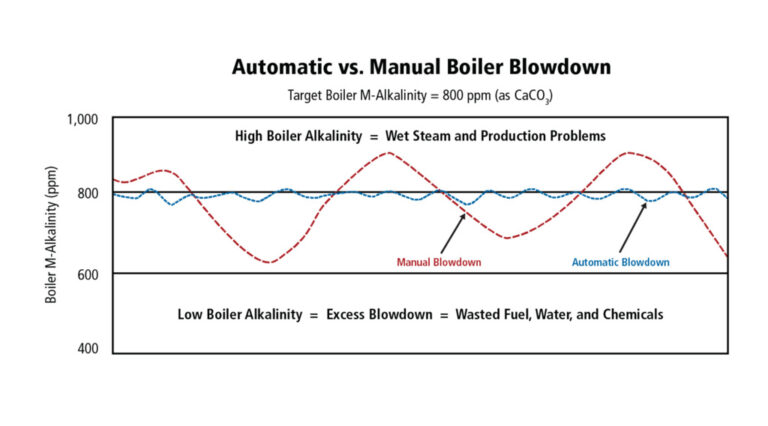

Our precision chemical dosing safeguards heated water systems against common issues like scale, corrosion, deposition and carry-over. For steam boilers, we can also employ advanced blowdown management to control dissolved solids, maintaining optimal operating conditions.

Proactive Maintenance & Control Programmes

With proactive maintenance and control programmes, our experienced personnel work in partnership with you to identify and resolve potential issues early, targeting uninterrupted performance and minimal downtime. This approach supports the long-term reliability and safety of your steam and hot water systems.

Benefit from Chem-Aqua’s Water Treatment Solutions

Enhanced Efficiency

Our water treatment solutions prevent scale and corrosion, delivering optimal heat transfer, reduced energy consumption, and improved system performance.

Maximised Cost Savings

Optimised water treatment processes reduce water, energy, and chemical use, lowering operational costs and increasing sustainability.

Extended Equipment Lifespan

We protect your heated water systems from deposition and corrosion, minimising breakdowns and maximising the life of critical components.

Customised Solutions

We tailor water treatment programmes for steam boilers, hot water closed-loop systems to meet your specific needs.

Compliance and Safety

Chem-Aqua’s solutions follow industry standards, reducing health and safety risks while helping to maintain consistent operational performance in line with regulatory requirements.

Environmental Impact

Reduce your carbon footprint with solutions that optimise water use, minimise waste, and improve energy efficiency for sustainably greener operations.

Why Choose Chem-Aqua?

When it comes to optimising the operation of your heated water systems, Chem-Aqua stands out with a century of water treatment expertise and a commitment to delivering exceptional solutions. Here's how we help you achieve efficiency, reliability, and compliance:

Industry Leadership & Expertise

Comprehensive Services & Support

Commitment to Quality & Compliance

Automatic Controller Reduces Costs and Improves Steam Quality

Discover how Chem-Aqua helped a food & beverage plant improve steam production efficiency, reduce fuel consumption, and eliminate costly downtime.

- Client Story

- Chem-Aqua’s Solution

- Results

-

Client Story

In the heart the U.S., a food and beverage facility faced increasing operational costs due to high fuel consumption and recurring issues with wet steam. These steam inconsistencies disrupted production, jeopardizing the facility’s efficiency and quality of output. With steam production as the backbone of their process, they needed a reliable solution to maintain system integrity and reduce their rising expenses.

-

Chem-Aqua’s Solution

Chem-Aqua conducted an in-depth audit of the facility's boiler system, highlighting that manual blowdown control led to inefficiencies. By installing an automatic proportional blowdown control system, Chem-Aqua enabled the facility to optimize the blowdown rate and maintain consistent steam quality. The upgraded system automated blowdown adjustments, reduced energy waste, and improved the reliability of steam production.

-

Results

The new system generated remarkable results, reducing fuel consumption by over $30,000 per year, saving around 200,000 liters of water annually. The improved steam quality eliminated wet steam issues, allowing the plant to enhance overall production efficiency and minimize maintenance needs.

Start Your Heating System Efficiency Journey

Ready to enhance the performance and reliability of your steam boilers and hot closed-loop systems? Connect with Chem-Aqua today to schedule a consultation. Let’s work together to safeguard your heated water systems for long-term success.